The Backbone of the Build: Rough Carpenter Job Description

ChiselJobs Team

Published on 2/5/2026

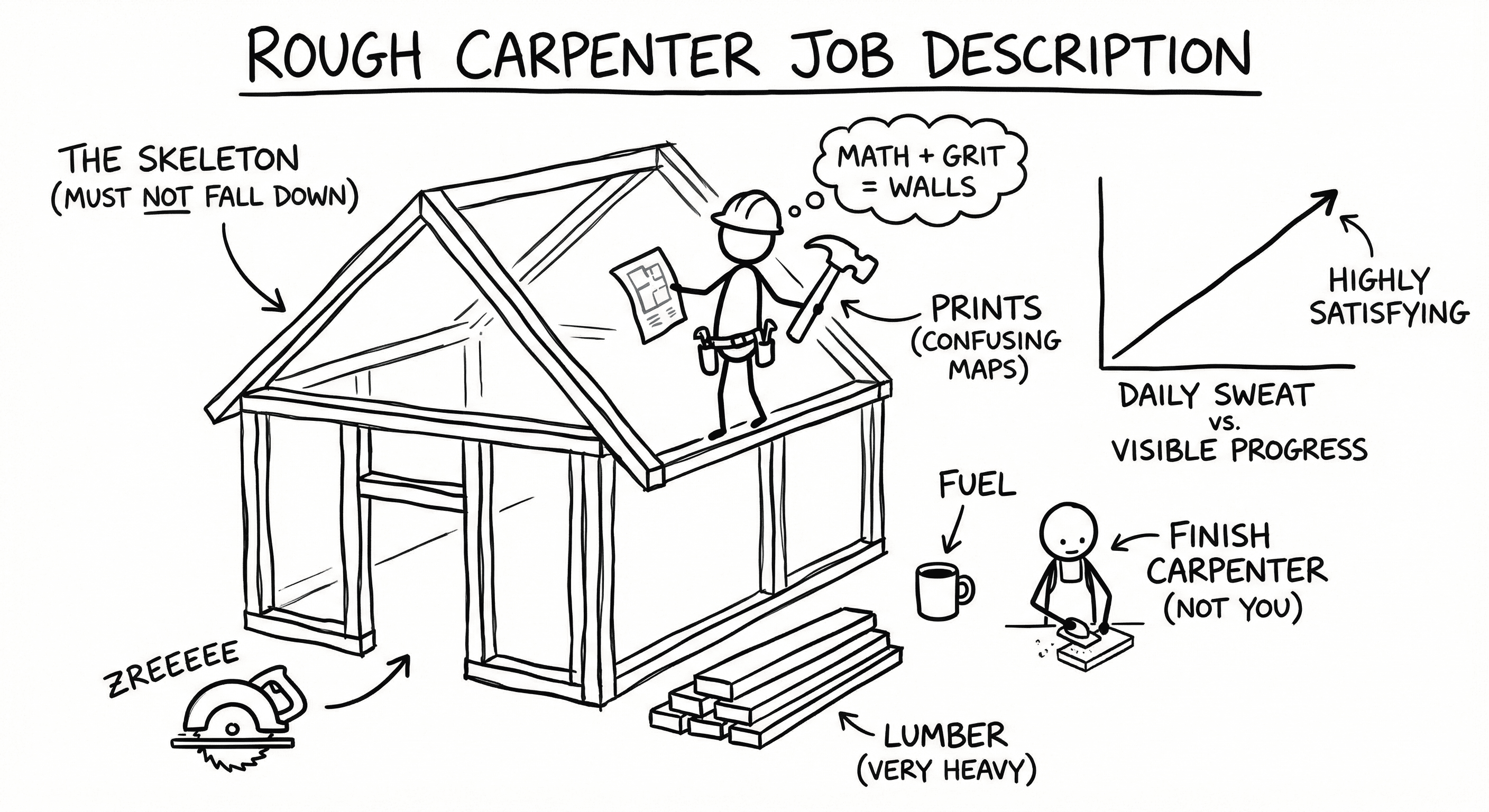

If you are looking at a career in the trades, you need to understand that rough carpentry is where the building starts to actually look like a building. It isn’t about making things pretty; it’s about making them stand up.

A rough carpenter builds the skeleton of the structure. You are the first woodworker on site and often the last to leave before the trades that cover up your work (drywallers, electricians) move in. This job description breaks down exactly what the role demands, from the tools you swing to the pay you can expect in the US and Canada.

What the Job Actually Is

Rough carpentry focuses on the structural integrity of a building. While finish carpenters worry about gaps in trim you can see with a microscope, rough carpenters worry about load-bearing walls, square corners, and level floors. You are working with structural lumber, plywood, and sometimes light-gauge steel.

Your main goal is framing. This means constructing the floor systems, walls, and roof trusses that define the shape and strength of the house or commercial building. You need to be able to look at a set of 2D prints and build a 3D structure that passes inspection.

Daily Grind: Key Duties

Employers don’t pay for standing around. On a typical site, your day involves heavy lifting and precision math. Here is what the work looks like:

Reading Blueprints: You must interpret architectural drawings to understand the layout. If you can’t read the print, you can’t build the wall.

Layout and Measuring: You will snap lines for walls and mark plate layouts. This requires a solid grasp of construction math—calculating rafter lengths, stair stringers, and determining square using the 3-4-5 method.

Cutting and Blocking: You will spend hours cutting studs, joists, and rafters. Speed and accuracy matters.

Vertical & Horizontal Framing:

Floors: Installing rim joists, floor joists (I-joists or dimensional lumber), and subflooring.

Walls: Assembling wall sections on the deck and lifting them into place. This includes framing window and door headers.

Roofs: Cutting and setting rafters or installing prefabricated trusses. This is often high-up work requiring fall protection.

Sheathing: Nailing plywood or OSB to the exterior to provide shear strength.

Code Compliance: Everything you build must meet local building codes regarding nail patterns, span tables, and fire blocking.

The Gear You Need

You can’t do the job without the right iron. Most employers expect you to have your own basic hand tools and belt (often called your "bags").

Personal Kit (Your Responsibility):

Framing Hammer: 20oz to 22oz. Heavier than a finish hammer to drive large nails fast.

Tape Measure: 25-foot or 30-foot "fat max" style tapes are standard.

Speed Square: Essential for marking 90s and 45s quickly.

Chalk Line: For snapping long, straight layout lines on subfloors.

Utility Knife: For cutting sheathing wrap, sharpening pencils, or trimming shims.

Cat’s Paw: A specialized nail puller for digging out misfired nails.

Levels: You usually need a torpedo level for small checks and a 4-foot level for plumbing walls.

Site Tools (usually provided by the contractor):

Circular Saw: The workhorse of the site. You need to be comfortable using a circular saw (often a "worm drive" or "rear handle" for more torque).

Pneumatic Nail Guns: Framing guns that shoot .131" or .148" nails. You need to know how to clear jams and oil them daily.

Compressors and Hoses: Managing air lines so they don’t trip up the crew.

Reciprocating Saw (Sawzall): For demolition or cutting out bottom plates in door openings.

Safety and Physical Demands

This isn't an office job. The physical demands are real. You will be lifting lumber that weighs 50-80 lbs repeatedly. You will be climbing ladders and walking on narrow top plates 8 feet or higher off the ground.

Safety is critical. In the US, you need to follow OSHA 1926 standards covering fall protection (harnesses), eye protection (safety glasses), and hearing protection. In Canada, you follow provincial regulations like WorkSafeBC or WSIB, focusing heavily on CCOHS safety guidelines.

Key hazards include:

Falls: The #1 cause of injury.

Kickback: Improper saw usage can result in severe cuts.

Silica Dust: Cutting concrete or fiber cement requires respirators.

Paychecks: What to Expect

Money varies largely by whether you are union or non-union, and where you live.

United States:

Entry-Level (Apprentice): $18 - $22 per hour.

Journeyman/Experienced: $25 - $35 per hour.

High Cost of Living Areas (e.g., California, Northeast): Rates can go north of $45-$50/hr for union journeymen.

The Bureau of Labor Statistics puts the median at around $56k/year, but skilled framers in busy seasons often earn more with overtime.

Canada:

Apprentice: $20 - $27 CAD per hour.

Journeyperson: $32 - $45 CAD per hour.

Union Rates: In major hubs like Toronto or Vancouver, total packages (wage + pension + benefits) are significantly higher.

Skills and Qualifications

You don’t always need a degree, but you do need training.

Apprenticeships: The gold standard. You work under a pro for 3-4 years and take classes. In the US, the United Brotherhood of Carpenters (UBC) runs massive training centers. In Canada, programs like Red Seal certification validate your skills nationwide.

Trade Schools: Many vocational colleges offer 1-year certificates in residential construction or framing.

Soft Skills: You need to be reliable. Showing up on time is 50% of the job. You also need to communicate clearly—misunderstanding a foreman's instruction can cost thousands in wasted lumber.

Why Choose This Trade?

Rough carpentry is satisfying. You arrive at an empty lot in the morning and leave with a standing wall in the afternoon. There is high demand for skilled framers across North America because fewer young people are entering the trades. If you are willing to work hard and learn the math, you can move from carrying lumber to running your own crew in a few years.

Looking for verified carpentry jobs across the U.S. and Canada? Explore opportunities on ChiselJobs, the job board built for skilled trades.