Carpenter Job Description: The Complete Trade Guide

ChiselJobs Team

Published on 12/23/2025

Carpentry is the backbone of the North American construction industry. Whether it is erecting the skeleton of a new high-rise in Toronto or installing intricate crown molding in a heritage home in New England, carpenters are the hands that turn architectural drawings into reality.

For employers, writing an accurate carpenter job description means understanding that this trade is not a monolith. It requires specific skills, physical grit, and a deep knowledge of building codes. For tradespeople, understanding the full scope of the role is the first step toward negotiating better pay or finding the right crew.

This guide breaks down the universal duties, essential tools, and specialized roles that define the modern carpentry trade across the U.S. and Canada.

The Core Scope of Work

At its heart, carpentry involves cutting, shaping, and installing building materials. While the day-to-day varies by job site, the fundamental responsibilities remain consistent for any skilled woodworker or builder.

Reading and Interpreting Blueprints

Before a saw touches lumber, a carpenter must understand the plan. You need the ability to read architectural drawings, sketches, and specifications. This includes calculating dimensions, estimating materials (takeoffs), and spotting potential structural clashes before they become expensive mistakes.

Layout and Measurement

Precision is non-negotiable. Carpenters are responsible for the layout of buildings, walls, and structures. This involves using tape measures, laser levels, and transit levels to ensure everything is square, plumb, and true. A framing carpenter might layout wall plates on a subfloor, while a finish carpenter marks reveal lines on a door jamb.

Cutting and Shaping Materials

Carpenters work with more than just wood. You will cut and shape drywall, fiberglass, plastic, and lightweight steel. Mastery of cutting tools—from the chop saw to the jigsaw—is required to produce tight joints and structurally sound components.

Assembly and Installation

This is the physical execution of the trade. It includes:

Structural: Erecting wall studs, floor joists, rafters, and trusses.

Exterior: Installing siding, windows, and roofing components.

Interior: Hanging drywall, setting cabinets, and fitting doors or trim.

Code Compliance and Quality Control

A carpenter acts as the first line of quality control. You must ensure all work meets local building codes (such as the IBC in the US or NBCC in Canada). If a wall isn't plumb or a header is undersized, the carpenter is expected to catch it and fix it.

The Carpenter’s Toolkit

A carpenter is only as good as their tools. While contractors often provide large power equipment, professionals are expected to arrive with their own belt and hand tools.

Essential Hand Tools

Every carpenter needs a personal kit that travels with them:

Measuring: 25-foot tape measure, speed square, framing square, and chalk line.

Cutting & Striking: 20 oz framing hammer, utility knife, wood chisels (1/4" to 1"), and a cat’s paw (nail puller).

Fastening: Screwdrivers, nail sets, and pliers.

Power Tools and Machinery

Modern carpentry relies on efficiency. Proficiency with these tools is standard:

Saws: Circular saw (Skill saw), miter saw, reciprocating saw (Sawzall), and table saw.

Drills: Impact drivers and hammer drills.

Pneumatics: Framing nailers, finish nailers, and staplers.

Physical Demands and Safety Standards

Carpentry is an athletic profession. The job description almost always includes lifting requirements, typically between 50 and 80 pounds. You will spend days standing, climbing ladders, scaffolding, and working in awkward positions like crawl spaces or attics.

Safety is paramount. In the U.S., you must be familiar with OSHA 1926 standards for construction. In Canada, knowledge of provincial OH&S regulations is mandatory. This includes proper use of PPE (hard hats, steel-toe boots, eye protection) and fall arrest systems when working at heights.

Specialized Carpentry Roles

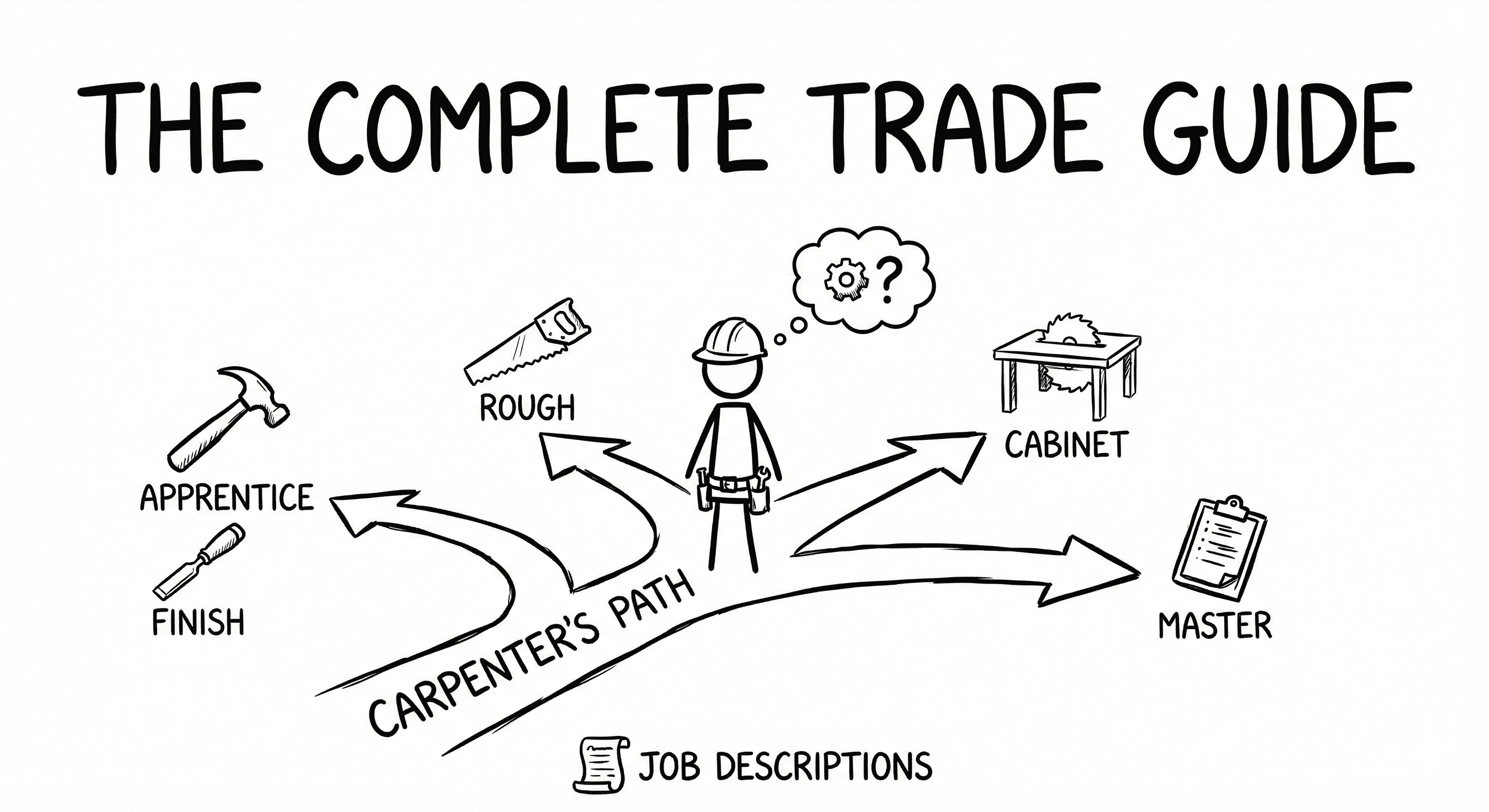

"Carpenter" is a broad title. Most job descriptions will specify a niche. Here is a high-level look at the primary specializations you will encounter on ChiselJobs.

Apprentice Carpenter

The entry point to the trade. An apprentice job description focuses on learning, material handling, site cleanup, and assisting journeymen with measurements and cuts. This role is about earning hours toward certification.

Rough / Framing Carpenter

These are the structural experts. A framer job description centers on building the skeleton of the house—floors, walls, and roofs. It is fast-paced, heavy work that requires excellent spatial reasoning.

Finish / Trim Carpenter

The detail-oriented artist. A finish carpenter job description involves installing visible elements like baseboards, crown molding, doors, and wainscoting. Precision here is measured in fractions of an inch.

Cabinet Maker / Joiner

Shop-based woodworkers who build furniture, cabinetry, and shelving. This role relies heavily on stationary machinery and intricate joinery techniques.

Formwork Carpenter

Specialists in concrete. These carpenters build the temporary molds (forms) that hold wet concrete for foundations, bridges, and high-rises. It involves heavy lifting and working with rebar.

Maintenance Carpenter

The generalist. Often employed by hospitals, schools, or property management firms, these carpenters handle repairs, door adjustments, and minor renovations across a facility.

Qualifications and Certification Path

While you can enter the trade as a laborer, career progression usually requires formal training.

United States: Most skilled carpenters complete a 3 to 4-year apprenticeship program, often through unions like the UBC or training bodies like NCCER. "Journeyman" status is achieved after completing specific hours and technical training.

Canada: The Red Seal Endorsement is the gold standard. It allows a carpenter to work anywhere in the country. Achieving Red Seal status typically requires 7,200 hours of apprenticeship and passing a rigorous national exam.

Job Outlook and Salary Expectations

The demand for carpenters in North America remains high due to a shortage of skilled tradespeople and an aging workforce.

Salary Range: Pay varies wildly by region and specialization. Entry-level helpers may start near minimum wage, while experienced union journeymen in major metros (like New York, San Francisco, or Vancouver) can earn over $45/hour plus benefits.

Growth: The push for residential housing and infrastructure renewal ensures steady work for those willing to travel or specialize in high-demand niches like concrete forming or custom finish work.