Pricing Guide: How Much to Charge for Cabinetry Side Jobs

ChiselJobs Team

Published on 12/17/2025

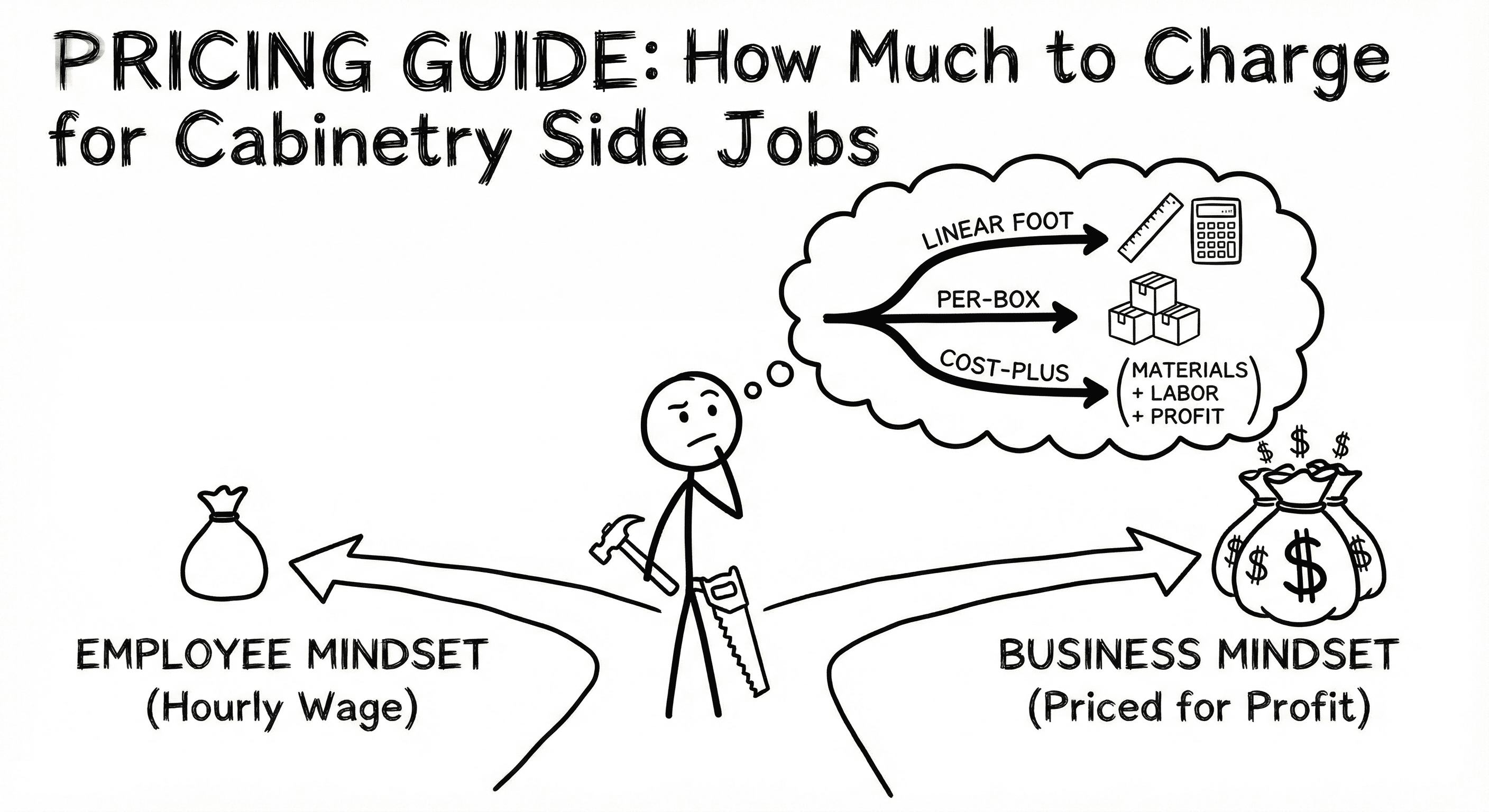

You have spent years honing your craft. You can scribe a filler strip to a bowed wall with your eyes closed and you know exactly how to dial in a soft-close hinge. Taking on private cabinetry work on the weekend feels like the logical next step to boost your income. You have the tools and the talent. But the quickest way to turn a profitable side hustle into a nightmare is pricing your work like an employee rather than a business owner.

This guide breaks down exactly how to price cabinetry side jobs. Whether you are fabricating custom built-ins or simply installing pre-fab boxes, you need a strategy. We will look at data-backed pricing structures so you get paid for your skill, not just your sweat.

Understanding the Market Rates

Before you quote a single job, you need a baseline. You might know what you earn per hour on a W-2 paycheck, but independent contracting is a different animal.

According to freelancer and contract data aggregated by ChiselJobs, successful independent carpenters typically target a gross revenue that is 2.5 to 3 times their standard hourly employee wage. This multiplier accounts for the overhead you usually ignore, such as blade sharpening, vehicle wear, insurance, and unpaid estimation time.

If you usually earn $35 an hour on the job site, ChiselJobs data suggests your independent billing rate needs to be between $85 and $105 per hour to be truly profitable. This is not greed. This is the cost of doing business when you are the one responsible for every screw, error, and warranty call.

The Three Pricing Models for Side Work

Most carpenters default to an hourly rate because it is familiar. However, cabinetry is a product-heavy trade. Clients want a finished price, not an open-ended labor bill. Using a fixed pricing model protects you and gives the client confidence.

1. The Linear Foot Method

This is the industry standard for quick estimates, especially for installation-only jobs. You measure the total length of the cabinets. Uppers and lowers usually count separately. You then multiply by a set rate.

Common Rate Ranges:

Stock Cabinet Installation: $100 to $300 per linear foot. (Source from Angie's List)

Semi-Custom Installation: $200 to $500 per linear foot.

Custom Fabrication & Install: $500 to $1,200+ per linear foot. (Source from Ask a Cabinet Maker)

The advantage here is speed. You can walk into a kitchen, pull a tape, and give a ballpark number in ten minutes. The risk is that linear footage does not account for complexity. A ten-foot run of simple base cabinets takes half the time of a ten-foot run involving a lazy Susan, a farm sink cutout, and intricate crown molding. Use this for rough estimates only.

2. The Per-Box Method

This method works exceptionally well for installing RTA (Ready-to-Assemble) or IKEA-style kitchens. You charge a flat fee for every "box" you assemble and hang. It creates a very transparent invoice for the client.

Typical Box Rates:

Base/Wall Cabinets: $100 – $250 per box.

Pantry/Tall Cabinets: $300 – $500 per box.

Panels and Fillers: Charge these as half-boxes.

This protects you from clients who try to cram twenty cabinets into a small kitchen. More boxes equal more money, regardless of the square footage. It also accounts for the physical labor of moving boxes into the house, which can be half the battle.

3. Cost-Plus (The Safest Bet for Fabrication)

If you are building custom units from scratch in your garage or shop, never use a flat rate unless you have built that exact piece ten times before. Custom work has too many variables.

The Formula: (Material Cost + 20% Markup) + (Estimated Labor Hours × Shop Rate) = Price

The markup covers your time sourcing wood, driving to the lumber yard, and the wear and tear on your table saw blades. It ensures that if material prices spike between the quote and the purchase, you have a buffer.

Setting Your Shop Rate

Your side hustle rate should not be your day job hourly wage. As mentioned earlier, ChiselJobs analysis of trade contracts shows that underpricing is the number one reason side businesses fail in the first year.

You need to pay for your own circular saw blades, wood glue, biscuits, sandpaper, and gas. You also need to account for the "weekend premium." You are giving up your free time.

A solid baseline for a skilled carpenter doing independent side work is $60 to $100 per hour for labor. If you are doing high-end stain-grade work or complex joinery, that number should go higher. Do not apologize for this rate. You are bringing professional tools and years of experience to their home.

The Hidden Costs Most Carpenters Miss

The difference between a profitable job and a break-even nightmare often lies in the details. When you write up your quote, ensure you have accounted for these often-overlooked expenses.

Consumables and Fasteners

Do not give these away for free. A single kitchen install can burn through two boxes of screws, a tube of construction adhesive, and a pack of shims. You might use three different grits of sandpaper and a pint of stain just for touch-ups.

Rule of Thumb: Add 3% to 5% of the total job cost specifically for "shop supplies."

Scribing and Site Prep

Walls are never straight. Floors are never level. If you are installing floor-to-ceiling pantry units in an older home, you might spend four hours just scribing the side panels to match a bowed drywall surface. You need to verify the rough opening dimensions before you build anything.

The Fix: Always add a "site condition buffer" of 10% to your labor time for older homes.

Tear Out and Disposal

Clients often assume you will take their old cabinets away. If you do not have a truck and trailer, this is a massive hassle. If you do, you still have to pay dump fees.

The Fix: Line item "Demolition and Disposal" separately. Charge at least $300–$500 for the labor and dump fees. This makes it optional for them. They might decide to dispose of it themselves to save money, which saves you the backache.

Hardware Installation

Drilling for handles and pulls is high-stress work. One slip and you have ruined a door front that you just spent days building or weeks ordering.

The Fix: Charge per handle (e.g., $10–$15 per pull). It acknowledges the precision required and pays you for the risk. It creates a psychological check for the client to realize this is detailed work.

Materials: The Markup Debate

When you buy materials for a client, you act as a bank. You front the money for the plywood, the slides, and the hinges. You deserve interest on that loan.

Standard industry markup is 15% to 20%. This is not ripping people off. This fee covers:

The time you spent calculating the cut list.

The fuel used to transport materials.

The risk of warping or damage while the wood sits in your shop.

The time spent returning unused items.

If a sheet of maple plywood costs $120, the client pays $144. Be transparent about this if asked, but generally, this is just part of the "Materials" line item on the invoice.

Payment Terms: Protect Your Cash Flow

Never start a side job without a deposit. Cabinetry requires significant upfront capital for materials. If a client ghosts you after you have bought $2,000 worth of white oak, you are in a hole.

Standard Payment Schedule:

50% Deposit: Due upon signing. This books your time and pays for materials.

30% Progress Payment: Due when fabrication is complete (or when cabinets are delivered to the site).

20% Final Payment: Due upon completion of punch-list items.

This structure ensures you are never "upside down" on a project. You are always working with the client's money, not your own.

Estimating Labor: A Real-World Example

Let’s look at a hypothetical quote for a simple "Built-in Bookshelf" side job.

The Project: Two base cabinets with doors (paint grade) and open shelving above. Total width: 8 feet. Height: 9 feet.

1. Materials:

4 sheets of 3/4" Birch Plywood @ $80/sheet = $320

1 sheet of 1/4" backing = $40

Face frame poplar = $100

Hardware (hinges, shelf pins) = $60

Paint/Primer = $80

Subtotal: $600

Markup (20%): $120

Total Materials: $720

2. Labor (Fabrication):

Breaking down sheets/cutting: 3 hours

Assembly/Joinery: 5 hours

Face frames and doors: 4 hours

Sanding and Prep: 3 hours

Total Shop Hours: 15 hours @ $75/hr = $1,125

3. Labor (Installation):

Transport and load in: 1 hour

Leveling bases and scribing: 2 hours

Installing uppers and trim: 3 hours

Total Install Hours: 6 hours @ $75/hr = $450

4. The Final Price:

Materials: $720

Labor: $1,575

Total Quote: $2,295

If you had just guessed "two grand," you would have been close. But if you had guessed "$1,200" because it "doesn't look that hard," you would be working for less than minimum wage.

Handling "Scope Creep"

Side jobs are notorious for the "While You're Here" phenomenon. The client sees you have a drill and asks if you can fix a loose hinge on the back door or hang a picture.

If you do it for free, you devalue your time. Keep a "Change Order" mentality. If they ask for extra work, smile and say: "I can definitely take care of that. It will be an extra $50 for the adjustment. Do you want me to add that to the final bill?"

Most of the time, they will agree. It sets a boundary that your time is professional, billable time.

Sources & Further Reading

To ensure your pricing strategy is competitive and profitable, we referenced data and industry standards from the following trade resources:

2025 Installation Cost Averages: For a breakdown of current market rates for stock vs. custom installs, refer to the Modernize Kitchen Cabinet Installation Cost Guide.

Custom vs. Stock Pricing Trends: Nelson Kitchen & Bath provides recent data on how material costs have shifted the threshold for custom cabinetry pricing.

Labor Rate Benchmarks: Compare your hourly shop rate against national averages for independent tradespeople at HomeAdvisor.

Pricing Methodology: For deep dives into the "Cost-Plus" vs. "Linear Foot" debate among professional woodworkers, the Woodweb Knowledge Base is an essential archive.

Contractor Markups: Method CRM outlines the industry standards for material and labor markups to ensure business sustainability.

Cash Flow Management: Best practices for structuring construction payment schedules (Deposit/Progress/Final) can be found in NetSuite’s Construction Guide.

Looking for verified carpentry jobs across the U.S. and Canada? Explore opportunities on ChiselJobs, the job board built for skilled trades.