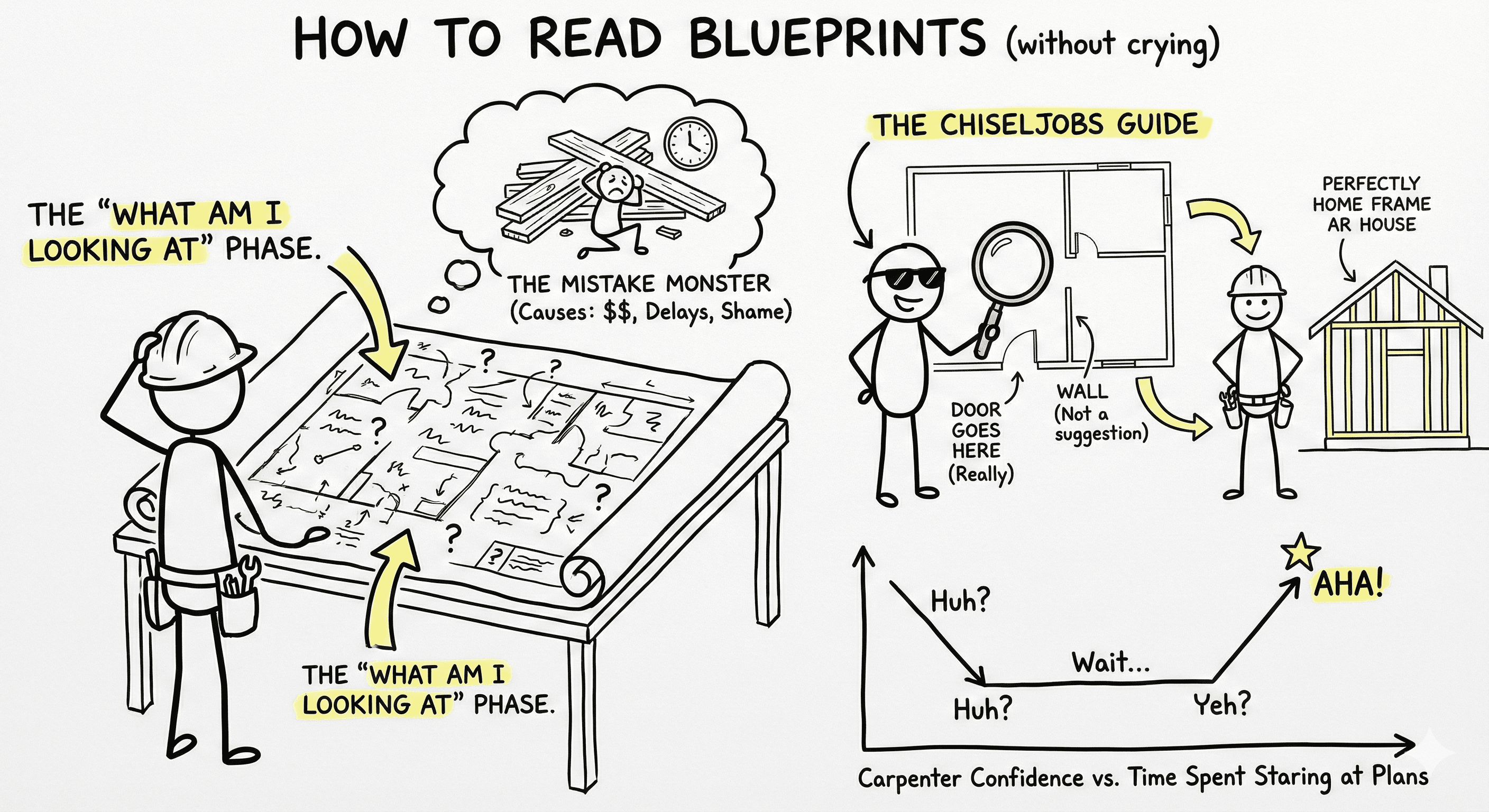

How to Read Blueprints: A Basic Guide for Carpenters

ChiselJobs Team

Published on 1/24/2026

This guide breaks down the essential language of blueprints, from the symbols used in framing to the subtle details found in finish carpentry, ensuring your next layout is spot-on.

The Anatomy of a Blueprint Set

Before diving into specific wall heights or joist spans, you must understand how a set of plans is organized. A standard set of construction drawings follows a logical sequence.

Title Block: Usually located in the bottom right corner, this is your project ID. It contains the project name, the architect’s contact info, and, most importantly, the Revision Date. Always check that you are working off the most current "Issued for Construction" set.

The Legend: This is your "Rosetta Stone." It defines the symbols and abbreviations used throughout the specific project. While many symbols are industry-standard, some firms use custom icons for specific hardware or materials.

Plan Index: A table of contents that helps you navigate between architectural (A), structural (S), mechanical (M), electrical (E), and plumbing (P) pages.

Mastering the Hierarchy of Lines

In carpentry, lines are instructions. The thickness and style of a line tell you exactly what it represents in the physical world.

Object Lines (Solid, Thick): These represent the visible edges of an object, such as the outer face of a 2x6 stud wall or the edge of a header.

Hidden Lines (Dashed): These indicate features not visible from the current viewpoint. For a framing carpenter, a dashed line on a floor plan might represent a header or a beam hidden inside a ceiling.

Dimension Lines (Thin with Arrows): These show the distance between two points. The number is usually placed in the center of the line. Never scale a drawing if a dimension is provided. Scaling can be inaccurate due to paper shrinkage or printing errors; always trust the written number first.

Center Lines (Long-Short-Long Dashes): These indicate the center of an object, such as a window opening or a structural column.

Understanding Scales and Proportions

Blueprints are a "shrunken" version of reality. In residential construction, the most common scale is 1/4" = 1'-0". This means every quarter-inch on the paper represents one foot on the job site.

As a carpenter, you should always carry an architectural scale ruler. However, for quick checks, a standard tape measure works if you know the math. At a 1/4" scale, a 4-foot wall will measure exactly 1 inch on the paper. For more detailed work, like cabinet installations or stair stringer layouts, architects often use a larger scale, such as 1/2" = 1'-0" or even 1" = 1'-0".

The Big Three: Plan, Elevation, and Section Views

To build a 3D structure from 2D paper, you have to look at the project from three different perspectives.

1. The Floor Plan (Bird’s Eye View)

Imagine taking a chainsaw and cutting a house horizontally 4 feet above the floor, then looking down. This view shows wall locations, door swings, and window openings. This is your primary map for layout and framing.

2. Elevation Views (Side View)

These show the vertical aspects of the build. You’ll use these to determine the height of window sills, the pitch of the roof, and the exterior finish materials. For finish carpenters, interior elevations are vital for determining the exact height of baseboards, chair rails, and wainscoting.

3. Section Views (The "Slice")

A section view is a vertical cut through a wall or the entire building. This is where the real carpentry details live. A wall section will show you the exact "sandwich" of materials: the mudsill, the rim joist, the wall studs, the sheathing, and the insulation. You can see standard wood framing examples at the American Wood Council.

Common Carpentry Symbols and Abbreviations

Space on a blueprint is limited, so architects use shorthand. Memorizing these common abbreviations will speed up your workflow:

Abbreviation | Meaning | Carpentry Context |

O.C. | On Center | Spacing for studs, joists, or rafters (e.g., 16" O.C.) |

P.T. | Pressure Treated | Used for mudsills or exterior decking |

B.O. | Building Opening | The rough opening (R.O.) needed for doors/windows |

TYP. | Typical | Means this detail applies to all similar areas |

CLG. | Ceiling | Used to denote ceiling heights or joist directions |

PL. | Plate | Refers to top or bottom plates in framing |

Safety and Compliance: Reading Between the Lines

Blueprints aren't just for dimensions; they are also for safety and code compliance.

OSHA Requirements: Notes often specify where temporary railings or fall protection anchors are required during the framing stage.

Structural Notes: These are non-negotiable. If a note specifies a specific Simpson Strong-Tie hanger or a certain number of 16d nails for a girder, you must follow it to meet building codes.

Egress Requirements: Pay close attention to window sizes in bedrooms. The "E" symbol often denotes an egress window required for fire safety according to the International Residential Code (IRC).

Pro-Tips for the Job Site

Highlighters are your friend: Use different colors to mark different phases. Use yellow for dimensions you've already laid out, red for mechanical conflicts, and blue for plumbing walls.

Verify the "Rough-In": Before you nail off your studs, cross-reference the architectural floor plan with the plumbing and electrical plans. Ensure your studs aren't blocking a 4-inch vent pipe or a recessed electrical panel.

Check for Revisions: In commercial work, "Delta" symbols (a small triangle with a number) indicate changes made after the first set was printed. Always look for the most recent Delta.

The "Measure Twice" Rule: If a dimension on the floor plan doesn't match the sum of the individual room dimensions, stop. Call the foreman or the architect. For high-precision layout, many contractors now use Leica Geosystems laser distance meters to verify plan accuracy on-site.

Conclusion

Mastering blueprint reading turns you from a person who follows orders into a person who leads the project. It allows you to anticipate problems before the first nail is driven and ensures the finished structure is safe, accurate, and professional.

Looking for verified carpentry jobs across the U.S. and Canada? Explore opportunities on ChiselJobs, the job board built for skilled trades.